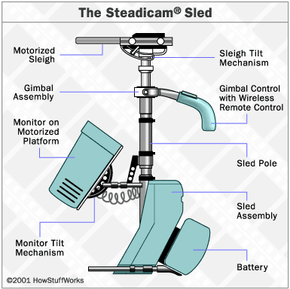

The Steadicam sled is the assembly that actually holds the camera equipment. A Steadicam operator moves the camera by rotating and tilting the sled pole, the central piece of the sled, which connects the various camera components. In the standard configuration, the monitor and battery are attached to the bottom of the sled pole, and the camera is attached to the top. Some Steadicams are reversible, so the cameraman can position the camera on the bottom and the other components on top. This makes it easier to get low angle shots.

In addition to moving with the pole, the camera can be pivoted up or down on its mount (called a sleigh), and in some Steadicams, the pole can telescope up and down. This lets the cameraman get high angle shots.

Other than holding the camera equipment, the sled's primary job is to provide balance. It achieves this by increasing the camera system's moment of inertia, or how resistant it is to rotation. This is determined by two factors: how much mass the object has and how far that mass is from the object's axis of rotation. Increasing mass makes an object harder to rotate, as does increasing the distance between the mass and the axis of rotation (a rolled out slab of clay, for example, is harder to rotate than a tight clay ball with the same mass).

Increasing the object's moment of inertia makes it harder to shake the camera unintentionally. One way to increase the moment of inertia would be to add more weight to the camera system, but this would make things harder for the cameraman. Instead, Garrett Brown decided to take the existing components of the camera and spread them out. This increases the distance between the axis of rotation and the mass of the total camera assembly, making the camera more resistant to rotation.

Expanding these components also shifts the camera assembly's center of gravity, or the point where the object's weight is balanced. When you hold an object precisely at its center of gravity, you can lift the object straight up because the downward pull of gravity is equal in all directions. You can balance a broom on your finger, for example, if you lift it at just the right spot between the bristles and the center of the broomstick. But if you place your finger anywhere else along the broomstick, gravity will pull more on one side than the other, and the broom will fall over.

In an ordinary camera assembly, the center of gravity is inside the camera itself. When you spread out the components, the center of gravity falls between the various pieces of equipment, along the sled pole. In a Steadicam, the articulated arm's gimbal grips the sled pole just above the center of gravity, in order to keep the camera from tilting in any direction on its own. The cameraman typically grips the sled pole at a point near the center of gravity, allowing him or her to control the camera more precisely.

Balancing the sled components correctly is a precision operation. The camera, monitor and battery have to be positioned just right so that the center of gravity falls near the gimbal. To make this adjustment easier, sophisticated Steadicams are outfitted with radio-controlled motors that move the various components by minute increments.

This makes it easier to balance the sled when the cameraman is getting ready for a shot, but it also allows the cameraman to make adjustments in the middle of a shot. This is an important feature, since the sled balance often changes during operation (for example, the weight of the film will shift as it moves through the camera). For some shots, the cameraman may want to shift the center of gravity away from the gimbal, so that the camera leans in one direction on its own. The balance can be adjusted with a joystick mounted on the sled grip, or remotely, with a radio-control unit.

In the next section, we'll see how Steadicam operators put all this technology to work to get remarkably smooth, hand-held shots.