The yo-yo is one of the most popular and enduring toys of all time. The ancient Greeks were playing with them more than 2,500 years ago, and there's some evidence that the Chinese had developed similar toys before that. In any case, the yo-yo has demonstrated phenomenal longevity -- it's older than any other toy except the doll.

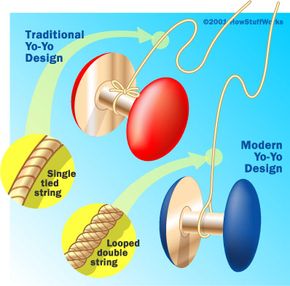

There have been several variations on the yo-yo design through the years. In the original design, which was still popular until the early 20th century, the string was tied securely to the axle. This design achieved huge popularity in Europe in the 18th and 19th century, where it had a number of names, including bandelore, quiz and L'emigrette.

In the modern yo-yo, brought to the United States from the Philippines in the 1920s (see below), the string is only looped around the axle. To understand the significance of this difference, let's examine the physical principles at work in both sorts of yo-yos.

In both designs, the yo-yoist winds the string tightly around the axle. Sitting in the yo-yoist's palm, the yo-yo has a certain amount of potential energy (energy of position). This potential energy takes two different forms:

- The yo-yo is held up in the air, giving it the potential to fall to the ground.

- The yo-yo has string wound around it, giving it the potential to spin as it unwinds.

When the yo-yo is released, both forms of potential energy change to kinetic energy. The yo-yo spool falls straight to the ground, which builds a certain amount of linear momentum (momentum in a straight line). At the same time, the string unwinds, and the spool spins, which builds angular momentum (momentum of rotation).

When the yo-yo reaches the end of the string, it can't fall any farther. But, because it has a good deal of angular momentum, it will keep spinning.

The spinning motion gives the yo-yo gyroscopic stability. A spinning object resists changes to its axis of rotation because an applied force moves along with the object itself. If you push on a point at the top of a spinning wheel, for example, that point moves around to the front of the wheel while it is still feeling the force you applied. As the point of force keeps moving, it ends up applying force on opposite ends of the wheel -- the force balances itself out. This phenomenon keeps a yo-yo's axis perpendicular to the string, as long as the yo-yo is spinning fast enough. (See How Gyroscopes Work to learn more.)

If the string is attached securely to the axle, as in the original design, the spinning axle will grip the string and start rewinding it; the yo-yo will travel back up the string. The yo-yoist must give a slight tug on the string as the yo-yo rewinds, in order to compensate for the energy lost to friction.

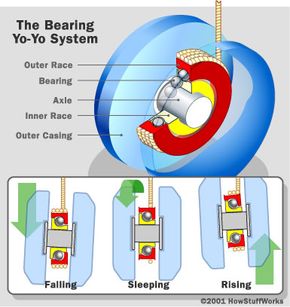

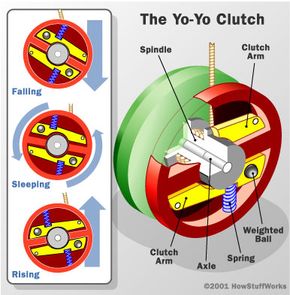

In the modern yo-yo, there is less friction between the string and the axle, since the string is only looped around the axle. When the spool completely unwinds, it will not automatically grip the spring -- it will simply spin freely. To get the yo-yo to rewind, the yo-yoist jerks on the string a little bit. This tug briefly increases the friction between the string and the axle so that the axle starts rewinding the string. Once it starts rewinding, this sort of yo-yo will return to the yo-yoist just like the older design.

The ability to make the yo-yo spool spin on the end of its string, or "sleep," made yo-yoing a much more interesting challenge. Yo-yoists try to keep the spool sleeping while making shapes with the string and swinging the yo-yo around them. Another trick is to "walk the dog" -- let the spinning spool roll along the ground before pulling it back in.

Over the years, manufacturers have come up with a number of mechanisms to make it easier to do these sorts of tricks. In the next section, we'll check out a few of the more popular variations found in modern yo-yos.