The Floor

At the Raleigh arena, Don MacMillan uses two large water filtration systems to produce deionized water, which is essential for making clear ice.

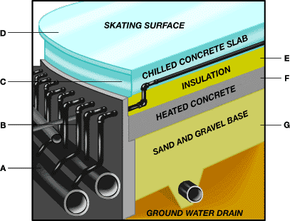

Underneath the floor at the Raleigh arena, you'll find a refrigeration system like the one shown below. This system consists of three main pieces:

Advertisement

- Chillers (the Raleigh arena has three)

- Steel pipes with 2,800 pipe welds

- Brinewater (an antifreeze agent)

Five miles (8 km) of steel pipe wind under the rink in the Raleigh arena (A). The three chillers cool the brinewater to 16 F (-9 C) and provide up to 270 tons of cooling (see How Air Conditioning Works for the definition of a "cooling ton"). The brinewater's chemical makeup keeps it from freezing.

The maintenance team sets the refrigeration system's temperature manually, based on indoor and outdoor temperatures. To freeze the rink surface, the system pumps 9,000 gallons (34,000 L) of freezing brinewater through the pipes and then onto the ice-bearing concrete slab.

The brinewater is pumped (B) into the pipes embedded in the ice-bearing concrete slab (C). The ice-bearing slab sits between the skating surface (D) and a layer of insulation (E), which allows the ice to expand and shrink as temperatures and time demand. The brinewater helps keep the ice-bearing slab's temperature just below 32 F so that the water spread onto it can freeze.

Underneath the layer of insulation, a heated concrete layer (F) keeps the ground below the ice from freezing, expanding and cracking the rink structure. The entire rink sits on a base layer of gravel and sand (G) which has a groundwater drain at the bottom.

To defrost the skating surface, the brinewater is heated and pumped through the ice-bearing concrete slab. This heats the under layer of the ice, making it easier to break up and remove with front-end loaders.