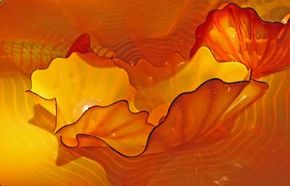

The practice of blowing glass may seem hip and modern if you've recently hit up an art exhibition by Dale Chihuly or Harvey Littleton, but the technique of glassblowing has actually been around since antiquity. Although not as old as simpler methods like bead making or cutting and carving shapes from larger pieces of glass, glassblowing has been all the rage since the time of the Roman Empire.

First century B.C. Syrians are most widely credited with the serendipitous discovery that glass could be blown from the end of a hollow tube into different shapes or molds -- a landmark event in the history of glass manufacturing [source: Encyclopedia Britannica]. Impressively, glassblowing techniques have evolved little since then. While new technologies have introduced more modern equipment, the fundamentals of glassblowing remain the same. But we'll get into those details in a second -- first we need to learn a little more about glass.

Advertisement

Glass is such a ubiquitous product that many of us don't ever give it much thought. But if you do stop to consider glass, one question that could pop into your head would be -- if it's a solid, how can it be transparent? Well this transparency is due to glass' interesting molecular structure: It's a solid, but with a molecular arrangement more akin to a liquid. In most solids, highly organized molecules are rigidly aligned and closely bound. In liquids, the molecules have weaker connections and are positioned more randomly. Known as an amorphous (noncrystalline) solid, glass, while it's rigid like a solid, has a randomized molecular structure like a liquid. This characteristic (also present in plastics and gels) is why glass is transparent -- light waves are better at penetrating through this type of arrangement than through other close-quartered solid molecular arrangements. For more about how this works, read What makes glass transparent?

In the meantime, it's enough to know that glass can be made out of combinations of many potential ingredients, which create varying levels of traits like transparency, strength and conductivity.

Advertisement